This week I ordered most of the material for my pole barn shed, finished clearing the construction site, had the material delivered and actually got started.

Getting the material delivered proved to be rather anti climatic right up to the point where the delivery guy began to back into the drive. I briefed him in advance on the extremely soft nature of the drive way material so as soon as he began to lose traction he spun the wheel, gunned the truck and dug an 18″ hole in the drive. Refusing my offer to tow him out so he could try another angle he commenced to use every tactic possible

material so as soon as he began to lose traction he spun the wheel, gunned the truck and dug an 18″ hole in the drive. Refusing my offer to tow him out so he could try another angle he commenced to use every tactic possible  to further the damage. In the end the material was literally dropped about 100 feet from its intended destination in a very mangled drive. He wasn’t happy with his tip and I wasn’t happy at the thought of

to further the damage. In the end the material was literally dropped about 100 feet from its intended destination in a very mangled drive. He wasn’t happy with his tip and I wasn’t happy at the thought of  hauling several tons of material an extra 100 feet.

hauling several tons of material an extra 100 feet.

I spent the rest of the day working on the drive with some painting thrown in for good measure. I did learn several lessons that afternoon. The first came as I was cutting the bands on some of the wood. Just as I cut the last band on a stack of 16 foot 4x4s it occurred to me that maybe I should have thought about it a bit more. As I was laying in the bushes with a stack of wood on top of me I made a mental note to bring a helper next time and tell him to cut the bands.

My next lesson came soon after when I began moving the 4x4s. I was feeling kind of good about then since I was prepared. I had on steel toed boots, heavy clothes, leather gloves then I reached down and picked up one them. In a flash a genetic memory surfaced as I stood there thinking “Holy shit! This is heavy!” Ancient cave men knew this which is why they invented the fulcrum. They didn’t know what to name it however and completely abandoned the idea. When ancient cave women started demanding a porch on their ancient caves the custom of knocking women in the head and dragging them back into the cave began.

I quickly dropped the post and gave a silent prayer to the steel toed boot god. With a bit of luck I managed to get a decent quantity of  lumber spread out and spent some time painting. I use a somewhat proprietary technique I call “Paint what you can reach, move, repeat.” Crude but it works. The plan is to paint everything with oil based

lumber spread out and spent some time painting. I use a somewhat proprietary technique I call “Paint what you can reach, move, repeat.” Crude but it works. The plan is to paint everything with oil based  enamel then paint when it’s cut. It will make for a longer construction time but I believe the added protection is well worth it. The paint also dries to touch in about 15 minutes which means a bit of planning/cutting ahead shouldn’t be all that bad. It also comes in my favorite color, olive drab.

enamel then paint when it’s cut. It will make for a longer construction time but I believe the added protection is well worth it. The paint also dries to touch in about 15 minutes which means a bit of planning/cutting ahead shouldn’t be all that bad. It also comes in my favorite color, olive drab.

That night it rained, a lot. After talking to a friend that is very experienced in this matter, we decided to wait a day and let the roads dry before venturing out. I used the day to rent a 12 inch auger and gas powered air compressor. The next morning we loaded up the auger and headed out. We were confident that we had an easy day ahead since the auger would be doing all the heavy work. Boy howdy were we wrong.

For starters, a 12 inch auger with a 5 horse power Honda engine is really heavy. And it’s tall. Just moving the thing after assembly took both of us going nearly all out. Another thing is roots. In sandy soil with no roots it’s no problem to dig a four foot deep hole. Just hold on to the thing and let it work. Maybe lift a bit occasionally to let the bit dump the soil. But when it reaches ground level you realize that you have to pull that thing out. And it doesn’t want to come out. It is designed to drill down, not up. With roots there’s a whole new dimension added which involves the blade hitting a root, stopping and you find your old white haired fat butt laying in the bushes  cause a 5 horse power motor is strong enough to toss you several feet. I’m glad my friend was able to shut it down before we lost complete control otherwise we would have spent the afternoon watching the handles spin around like some kind of medieval torture device until it ran out of gas. In the end we managed to dig the 24 holes for the foundation. Then the holes began to fill with water. By the end of the day our four foot deep holes had about two feet of water in them.

cause a 5 horse power motor is strong enough to toss you several feet. I’m glad my friend was able to shut it down before we lost complete control otherwise we would have spent the afternoon watching the handles spin around like some kind of medieval torture device until it ran out of gas. In the end we managed to dig the 24 holes for the foundation. Then the holes began to fill with water. By the end of the day our four foot deep holes had about two feet of water in them.

After six aspirin and two vodkas I slept well that night.

The next day it rained. I took the auger home then bought more supplies. I rented a trailer but was still to beat to do much loading. The following day we finished loading and bravely set off to build a pole barn. The 15 mile trip off the paved road took over two hours. At several points the trailer was simply cutting a trench through mud that was higher than the wheels on it. But we finally managed to get it on site.

Confident that we would get the corner posts set we set about  positioning equipment and material. Then Randy happened to look in one of the holes. Our four foot deep holes now had four feet of water in them. By then it was late so we packed up and left.

positioning equipment and material. Then Randy happened to look in one of the holes. Our four foot deep holes now had four feet of water in them. By then it was late so we packed up and left.

Getting the water out isn’t such a big deal. A shop vac will handle that. The question is whether the water is coming in from the bottom, sides or both. If mostly bottom we can plug the holes with a sack of dry concrete and some rebar. Then we just have to build the column from there. Since the first two feet of dirt coming out of the holes was mostly dry I believe that this will work. If not we may have to look at some really creative ways to set the posts in concrete then put them in the holes. I’m currently searching for an ancient man to help build a fulcrum.

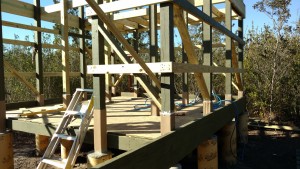

porch deck “mostly” then late yesterday afternoon put in two windows and the first layer of some of the siding. For security reasons I chose small windows that we mounted rather high in the wall. It’s hard to tell from this pic but the front door is pretty wide. I might decide to cut it back in the future but for now I’ve went with large so I can move equipment in and out easily.

porch deck “mostly” then late yesterday afternoon put in two windows and the first layer of some of the siding. For security reasons I chose small windows that we mounted rather high in the wall. It’s hard to tell from this pic but the front door is pretty wide. I might decide to cut it back in the future but for now I’ve went with large so I can move equipment in and out easily. Just some random pix. My DSL is still slow as sin so I have to que a whole slew of pix and post whatever it will upload. Another line item on my ever growing “To Do” list.

Just some random pix. My DSL is still slow as sin so I have to que a whole slew of pix and post whatever it will upload. Another line item on my ever growing “To Do” list. My plan was to spend the weekend out there but I’ll have to burn Saturday getting everything ready then hopefully drive out before dark. Of course that depends on whether we finish the siding plus seal the place well enough to heat with a kerosene heater. I would be OK in a sleeping bag but Ziggy absolutely refuses to sleep in one.

My plan was to spend the weekend out there but I’ll have to burn Saturday getting everything ready then hopefully drive out before dark. Of course that depends on whether we finish the siding plus seal the place well enough to heat with a kerosene heater. I would be OK in a sleeping bag but Ziggy absolutely refuses to sleep in one.

![IMG_20160201_131245204[1]](http://ishimo.com/wp-content/uploads/2016/02/IMG_20160201_1312452041-300x169.jpg)

![IMG_20160130_133615674[1]](http://ishimo.com/wp-content/uploads/2016/02/IMG_20160130_1336156741-300x169.jpg)

![IMG_20160201_160818492[1]](http://ishimo.com/wp-content/uploads/2016/02/IMG_20160201_1608184921-300x169.jpg)

![IMG_20160203_160320542[1]](http://ishimo.com/wp-content/uploads/2016/02/IMG_20160203_1603205421-300x169.jpg)

![IMG_20160126_093532292_HDR[1]](http://ishimo.com/wp-content/uploads/2016/01/IMG_20160126_093532292_HDR1-300x169.jpg)

![IMG_20160128_121905659[1]](http://ishimo.com/wp-content/uploads/2016/01/IMG_20160128_1219056591-300x169.jpg)

![IMG_20160128_150644857[1]](http://ishimo.com/wp-content/uploads/2016/01/IMG_20160128_1506448571-300x169.jpg)

![IMG_20160128_144744469[1]](http://ishimo.com/wp-content/uploads/2016/01/IMG_20160128_1447444691-300x169.jpg)

![IMG_20160130_164708244_HDR[1]](http://ishimo.com/wp-content/uploads/2016/01/IMG_20160130_164708244_HDR1-300x169.jpg)

![IMG_20160130_160955363[1]](http://ishimo.com/wp-content/uploads/2016/01/IMG_20160130_1609553631-300x169.jpg)